t’s critical to keep your shaft alignment perfect for making your operations efficient and cost-effective. Investing in a shaft alignment system boosts production, reduces downtime, lowers expenses, and even helps the environment. Machines must be available 24 hours, seven days a week, with minimal downtime. A machine failure results in a significant loss of production. Misalignment is responsible for about half of all machine failures. Shaft alignment can be done with a variety of tools. The simplest method is to use a ruler or straight edge over the two connecting portions and align them by sight. The result is not very exact and relies on the operator. Mechanical dial indicators can produce a better result. A trained and experienced operator can obtain accurate and reliable measurements.

Using laser-based alignment technologies is a much easier and more precise method. In addition, they don’t necessitate any specific talents and provide accurate and consistent outcomes.

What Are The Benefits of Laser Alignment?

The most effective way to keep your machinery aligned is to use laser alignment. Laser alignment is more precise than previous methods and takes less time to complete.

Downtime is Reduced

Reduced downtime is one of the fundamental benefits of keeping appropriate shaft alignment. One of the most prevalent consequences of misaligned equipment is lost production time; roughly half of all rotating machine faults are caused by incorrect alignment. Maintaining appropriate alignment reduces unplanned downtime due to equipment failure and extends the equipment life cycle, allowing you to stay in full production for longer.

Cost-Effectiveness

When a machine is working smoothly, it requires less unscheduled maintenance and repairs. Furthermore, because laser alignment minimizes the risk of machine failure, the components are less likely to be damaged or fail, minimizing the need to build or order extra materials. Your facility will be able to run at a greater degree of cost-effectiveness as maintenance, repairs, and materials orders are reduced.

Consumption Of Energy is Reduced

Inefficient machines consume more energy to operate, and misaligned equipment can lead to the leakage of hazardous fluids into the environment. On the other hand, an adequately aligned machine can save a lot of energy, which means lower costs for you and less pollution for the environment.

Inventory Costs Are Lower

When machines are correctly aligned, fewer parts need to be replaced (bearings, couplings, seals, etc.). This can result in a reduction in spare/replacement part inventories.

Increased Equipment Life

Machines that are misaligned vibrate excessively. The flexible coupler and the machine enclosure do not absorb the forces created. Bearing life is shortened due to the vibrations being communicated to the bearings. The forces can potentially harm seals. Relationship between bearing life cycle and offset: The longer the projected bearing life cycle, the smaller the offset misalignment.

Repairs Are Less Likely To Occur

When precision alignment is performed regularly, mechanical seal repairs can be reduced by 65%. When precision laser alignment becomes an integral element of the pump repair plan, the rate of repairs drops by up to 30%. Parts costs and inventory levels are also lowered, lowering maintenance expenses.

What Is the Importance Of Shaft Alignment?

Correctly aligned shafts result in numerous benefits:

- First, increased machine productivity and availability equal guaranteed production.

- Increased bearing and seal service life mean fewer replacement components are required.

- Complete seals equal less leakage and a more pleasant working environment.

- Overheating and secondary damage are reduced when the lubrication film is used optimally.

- Lubricant leakage is reduced, which means less lubricant is consumed.

- A reduced level of noise Equals less vibration.

- A lower likelihood of significant malfunctions equals a safer working environment.

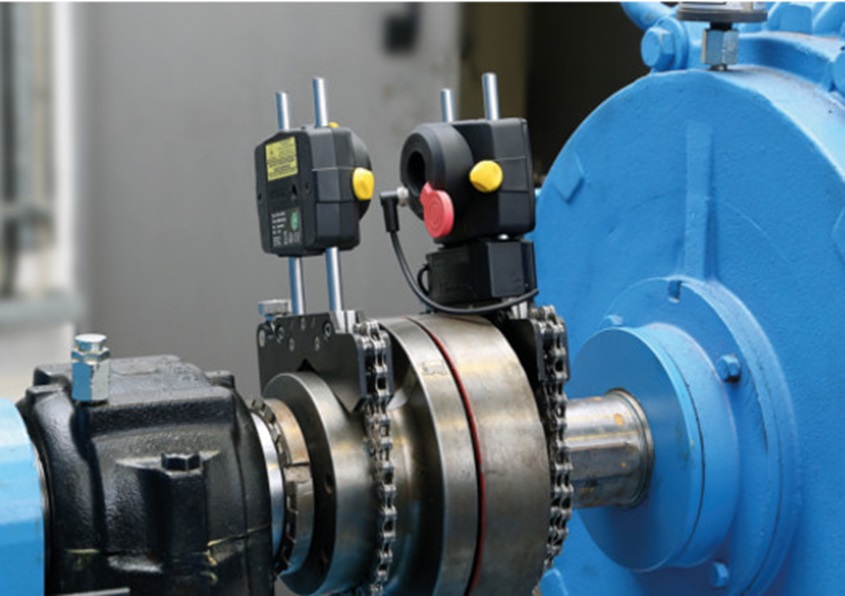

All of this is possible using EASY-LASER’s shaft alignment tools. With the new display unit from our XT Generation of laser shaft alignment instruments, you can also take pictures and infrared images of the machine. You can e-mail the report from the display to your customer or keep it for your own records when you’re done.